Article

Smoke and air ventilation in ETFE Structures

Back to listBeing a relatively new material in the building industry, the installation of an ADAS® ETFE Skylight usually brings about questions pertaining to its performance. As such, this article addresses a common yet important concern amongst designers and engineers: Smoke and air ventilation.

Smoke ventilation

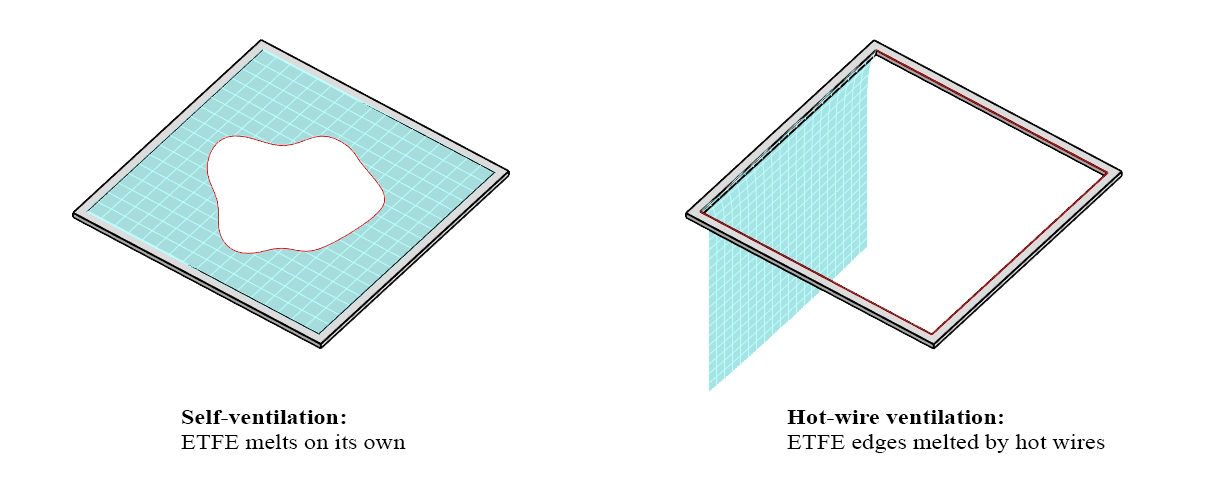

In fire safety, one of the most crucial aspects is to ensure the ventilation of smoke from a burning structure to prevent suffocation. With an ETFE roof or façade system, there are three ways in which smoke ventilation can be ensured. Firstly, the low melting point of ETFE film means that in temperatures above 200°C, the film will melt away resulting in self-ventilation of the space. Melting ETFE does not produce hot droplets that will fall onto passersby below, and is thus a safer solution than traditional roofing materials under these conditions.

In the event of the temperature not reaching 200°C, the second method would be to install conventional smoke ventilation systems within the ETFE structure, which can be activated by a smoke detection system. However, this method does not take advantage of the properties of ETFE, namely its flexibility and low melting point.

The third method utilizes a hot wire system installed around three of the supporting edges of the ETFE film. Upon detection of a fire, the wires heat up and melt the ETFE membrane, which causes it to drop and create a 100% opening within 90 seconds. Although this system must be replaced after activation, it only costs 10% of conventional ventilation systems, and is a lot less bulky as well.

Air ventilation

Unlike traditional glass or metal roofs, ETFE can be designed to provide better ventilation as its light weight and flexibility create more room for architectural freedom and structural innovation. This means that aesthetic qualities can be achieved alongside form considerations that enable the best conditions for natural ventilation.

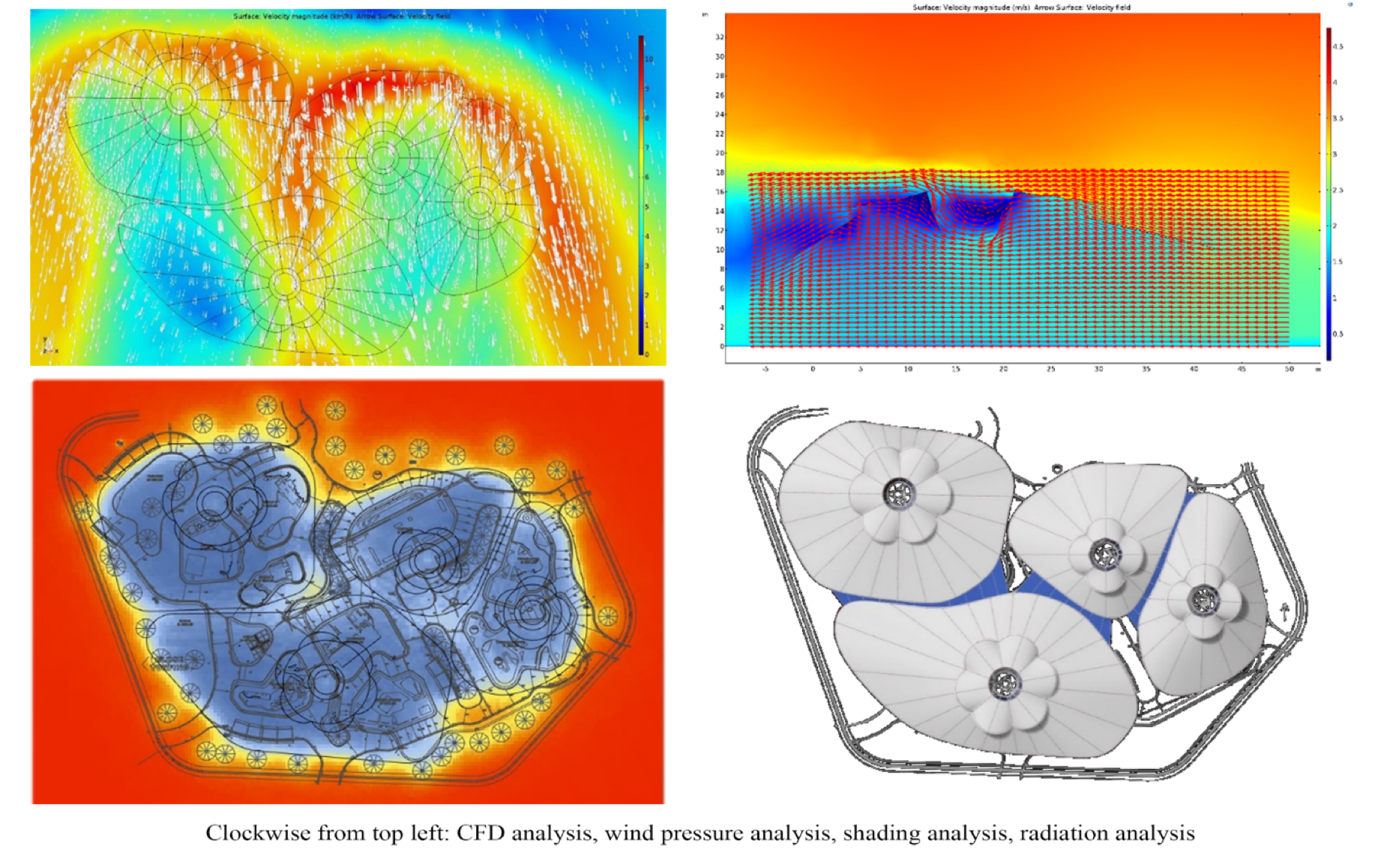

At ADAS, we possess the expertise that can only be acquired from years of experience and hundreds of projects worldwide. Apart from design and build, ADAS also carries out in-house advanced analysis including radiation and CFD analysis.

Our in-house ADAS® CFD Analysis not only studies how the structure performs under high wind loads but also seeks to understand the ventilation and human comfort performance of each design. Radiation analysis is used to understand the sunlight direction and the temperature difference between the exterior and interior environments of the ETFE structure throughout the day.

Conclusion

As our architects and engineers work closely within each project, these analyses can be carried out to address initial design issues in order to maximize ventilation performance and human comfort levels. Furthermore, the installation of an ETFE roof or façade system is undeniably safer than conventional glass roof systems in terms of fire safety, and its flexible properties can only result in more room for innovation.

By incorporating these considerations into the process of design and engineering, our expertise allows us to consider multiple solutions towards achieving the optimum performance of every ADAS® ETFE Skylight system.

Sources:

ETFE: Technology and Design by LeCuyer

ADAS® In-house analysis